Pink EVAVISION transparent EVA interlayer film for laminated safety glass

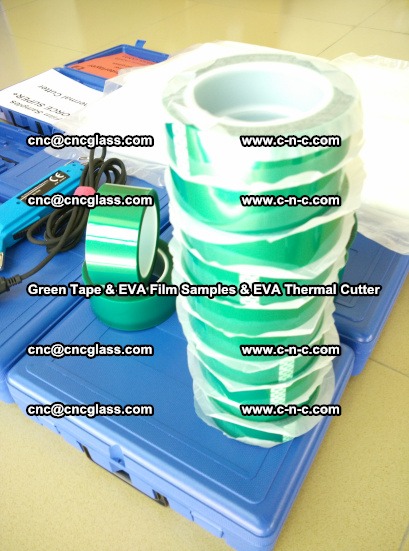

EVA FILM samples, Green tapes, EVA thermal cutter, for safety glazing

Comparing Light Transmittance of CNC Glass Interlayer EVA Film: EVAFORCE EXTREME

Written by Peter Lin

Spectrophotometer Light Transmittance of Super Clear EVA Film Samples of an international famous supplier

1-Tester: Peter Lin

2-Test Time: May, 26, 2014.

3-EVA Film Samples: Super Clear EVA Film Samples of an international famous supplier

4-Laminating Time and Temperature: 85°-15′130°-40′

320nm

Wave Length 340 360 370 380 390 530nm

2.4% 1.5 3.8 9.1 22.1 50.7 88.3%

Spectrophotometer Light Transmittance of CNC Glass Interlayer EVA Film: EVAFORCE EXTREME

1-Tester: Peter Lin

2-Test Time: May, 26, 2014.

3-EVA Film Samples: EVAFORCE EXTREME of CNC Glass Interlayer

4-Laminating Time and Temperature: 85°-15′130°-40′

320nm

Wave Length 340 360 370 380 390 530nm

2.4% 1 0.7 0.9 2.1 1.8 87.1%

Visible Light Transmittance Comparing

Time&Temperature 85℃-15′

130℃-40′ 85℃-15′

130℃-90′ 85℃-15′

140℃-20′ 85℃-15′

140℃-40′

EVAFORCE EXTREME 91.05 91.03 90.30 90.80

Super Clear EVA Film Samples of an international famous supplier 90.83 91.50 91.08 91.05

Conclusion:

EVAFORCE EXTREME of CNC Glass Interlayer performs better in transparence and UV radiations blocked.

EVAFORCE EXTREME Interlayer Film is the best choice to protect the human beings and furnitures inside building from the harmful UV radiations while offering the best transparence to fulfill the duty of glass as it should be.

EVA FILM

EVAFORCE® EXTREME

*Super Clear

*For Architectural Safety Laminated Glass

*Less Overflow When Heating

*Strengthened Mechanical Properties

*Recommended For Extreme Environments

*Best Choice For Curved Glass Laminating

*Applied Both Indoor And Outdoor

*Replacing PVB Film

Properties of laminating safety glass with pvb interlayer film

Properties of Laminating Safety Glass with PVB Interlayer Film

http://en.calameo.com/read/000628737946624532ca3

Autoclave when laminating safety glass with PVB interlayer film

Pre pressing pre-laminated glass with polyvinyl butyral pvb film

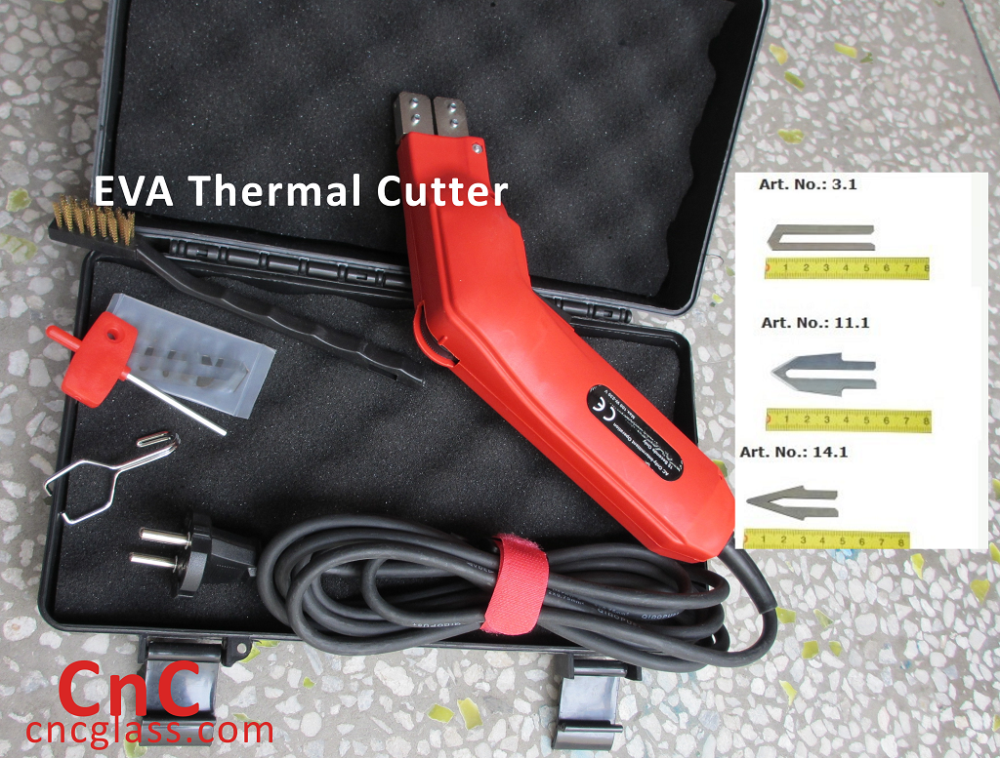

Electric heating cutter available in several blades to remove the remains of EVA of laminated glass

EVA Thermal Cutter

Electric heating cutter available in several blades to remove the remains of EVA of laminated glass

For details, please read this product page: http://cncglass.com/eva-thermal-cutter-hot-knife/

Silicone Vacuum Bag for EVA Laminating Glass Machine

This silicone bag sealed and easy to use allows to laminate glass sheets on the horizontal method.

Light Measuring Equipment UV + VI + IR

For laminated glass

UV=Ultra Violet

VI=Visible Light

UR=Infrared

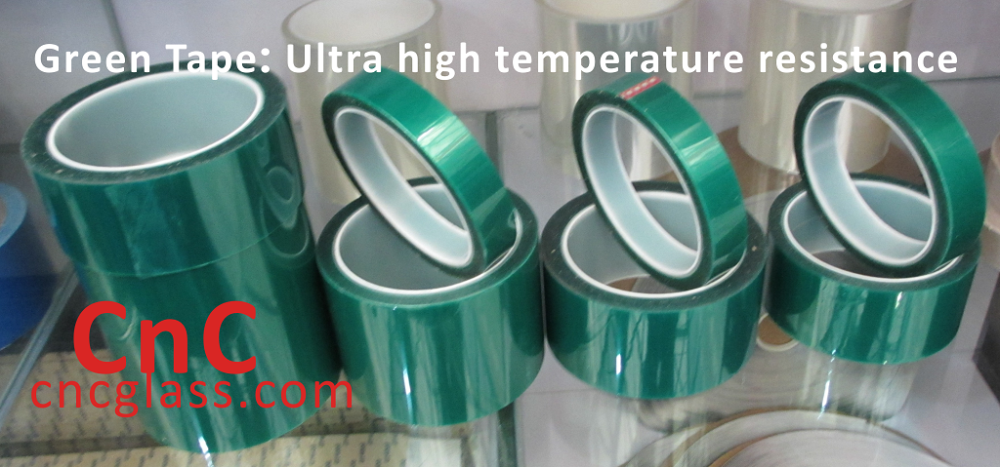

Green RibbonTape: Ultra high temperature resistance

Thermal ribbon for laminate with vacuum bag.

Maximum supported temperature: more than135 º C

Contact Us

CNC-INTERLAYER TECH:

【Product】CNC-Shield® PVB INTERLAYER FOR AUTOMOTIVE WINDSHIELD GLASS [email protected]

【Product】CNC-Force® EVA INERLAYER FOR ARCHITECTURAL LAMINATED GLASS [email protected]

【Product】CNC-Smart® SMART FILM FOR PRIVACY SWITCHABLE GLASS [email protected]

Web: www.CNCnext.com www.HelloGlass.com www.CNCglass.com

Mail: [email protected]

HOW TO MAKE PVB LAMINATED GLASS WITH PVB FILM POLYVINYL BUTYRAL(2-2)

HOW TO MAKE PVB LAMINATED GLASS WITH PVB FILM POLYVINYL BUTYRAL(2-2)

By Peter Shin

www.HelloGlass.com

All rights reserved by CNC-INTERLAYER TECH:

【Product 1】CNC-Force EVA INERLAYER FOR ARCHITECTURAL LAMINATED GLASS [email protected]

【Product 2】CNC-SmartSMART FILM FOR PRIVACY SWITCHABLE GLASS [email protected]

【Product 3】CNC-Shield PVB INTERLAYER FOR AUTOMOTIVE WINDSHIELD GLASS [email protected]

Web: www.CNCglass.com www.CNCnext.com www.HelloGlass.com

Mail: [email protected]

[email protected]/

[email protected]

SILICONE LAMINATE BAG FOR EVA LAMINATING MACHINE [email protected]

SILICONE BAG FOR PVB AUTOCLAVE VACUUMING [email protected]

www.ucolin.com www.silicone4.com

If the air is not expelled completely:

Bubbles may appear;

It may cause delamination;

The laminated glass’ thermal stability is not good;

The glass may get cracked inside the autoclave.

======================================================

=====================================

Air expelling, prepressing and edge sealing when making PVB laminated glass

Two ovens and two times of roll extrusion

Clean the glass

Temperature: 20-25℃, humidity:25%+/- 2%

Prepressing oven

Prepressing oven

Combining room:

The first oven’s temperature:

the pre-laminated glass may get crack if the temperature is too low

The pre-laminated glass edge will get sealed earlier than expected if the temperature is too high

The second oven’s temperature:

If temperature is too low, the pre-laminated glass edge can not be sealed smoothly and the adhesion is not good;

If temperature is too high, bubbles will be produced.

=================================================================================

Conditions for prepressing and expelling air when laminating glass with PVB Film

Roll extrusion way on the flat layer:

The first roller: the glass surface temperature is about 35℃, with pressure 5-7 bar; and the gap between two rollers is about 10% smaller than the glass total thickness.

The second roller: the glass surface temperature is 65-75℃,with pressure 5-7bar; and the gap between two rollers is 15% -20% smaller than the glass total thickness.

Vacuuming way on the curved laminating layer:

Vacuum ring: silicone vacuum bag

Cold pumping:

Temperature : 20-30℃; 22℃ is suggested.

Vacuum degree: 550 -660mm HG;

Time: About 5-20 minutes.

Heat pumping:

Glass surface temperature: 95-105℃

Time: less than 25 minutes

====================================================

Air expelling when laminating safety glass with PVB Film

Factors affecting normal air expelling:

Temperature required for glass is lower than 25℃, and for PVB lower than 18 ℃。

Cold pumping time is at least 5-20 minutes, with temperature 22℃.

Vacuum degree: absolute vacuum 80% (latm/100kPa)

Vacuum ring’s temperature: lower than 30 ℃. 20-25 ℃ is recommended.

Rheology and the grains on PVB Film’s surface

Glass’s thickness

Each glass is not matched very well to the other glass after hot bending

====================================

All Rights Reserved By:

UCOLIN SILICONE TECH

(1)-Silicone Vacuuming Bag for EVA Glass Laminating Machine/Privacy Glass Laminating

(2)-Silicone Sheet for EVA Glass Laminating Machine

(3)-Silicone Bag for PVB Glass Laminating Auto-clave

(4)-Silicone Rubber Sheet for Solar Cell Module Laminating Machine

(5)-Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine Vacuum Filming Machine

Contact Us: [email protected] / www.ucolin.com

[email protected]/ [email protected]

=====================================

Autoclave when laminating safety glass with PVB interlayer film

Purpose:

Dissolves the residuary air inside the PVB film

Allows PVB film flows and combine with the glass

Obtain required performance and transparency

Basic condition and requirement:

Temperature and pressure can get increased simultaneously, but the pressure can not get increased to quickly.

Pre-laminated Glass’s constant temperature: 135-145℃

Pre-laminated Glass’s pressure under constant temperature: 12-14 bar

Time for constant temperature and pressure: at least 20 minutes

Temperature for releasing pressure: under 50℃

=================================

Autoclave’s working principle when laminating safety glass with Polyvinyl Butyral PVB film:

PVB film:

shapeless polymer

Appears adhesive under low temperature

Appears flowable under high temperature

Temperature: enable the PVB film to flow and get shaped permanently

Pressure: enhance the adhesion between PVB film and glass

Time: allows PVB film to become flowable

Notes: the thicker the glass, the longer time for the autoclave’s cycle.

===========================================

Common problems for autoclave when laminating safety glass with Polyvinyl Butyral PVB film

=Pressure get increase too quickly: the PVB film stays cool inside the autoclave; and it will cause the air running through if the glass edge was not sealed well or hot bending did not go well.

=Pressure get increase too slowly: the air rest inside the PVB film will get expanding if the temperature increases too fast, and becomes bubbles that will rift the glass edge.

=the time for constant temperature and pressure is too short:

The PVB film does not flow completely, and so it can not got contact with the glass completely

The adhesion becomes worse;

The glass clearness will get reduced consequently

=the temperature is too high when releasing pressure:

The PVB film is still too hot and soft at the meantime;

The high pressure air get together inside the glass edge, and get saturation;

If the pressure reduce too suddenly, the air under high pressure will get expanded inside the soft film and becomes bubbles;

The air under high pressure will diffuse from the glass center to the glass edge and later becomes bubbles because the pressure in the edge is lower.

All Rights Reserved By:

UCOLIN SILICONE TECH

(1)-Silicone Vacuuming Bag for EVA Glass Laminating Machine/Privacy Glass Laminating

(2)-Silicone Sheet for EVA Glass Laminating Machine

(3)-Silicone Bag for PVB Glass Laminating Auto-clave

(4)-Silicone Rubber Sheet for Solar Cell Module Laminating Machine

(5)-Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine Vacuum Filming Machine

Contact Us: [email protected] / www.ucolin.com

[email protected]/ [email protected]

HOW TO MAKE PVB LAMINATED GLASS WITH PVB FILM POLYVINYL BUTYRAL(2-1)

HOW TO MAKE PVB LAMINATED GLASS WITH PVB FILM POLYVINYL BUTYRAL(2-1)

By Peter Shin

www.HelloGlass.com

All rights reserved by CNC-INTERLAYER TECH:

【Product 1】CNC-Force EVA INERLAYER FOR ARCHITECTURAL LAMINATED GLASS [email protected]

【Product 2】CNC-SmartSMART FILM FOR PRIVACY SWITCHABLE GLASS [email protected]

【Product 3】CNC-Shield PVB INTERLAYER FOR AUTOMOTIVE WINDSHIELD GLASS [email protected]

Web: www.CNCglass.com www.CNCnext.com www.HelloGlass.com

Mail: [email protected]

[email protected]/

[email protected]

SILICONE LAMINATE BAG FOR EVA LAMINATING MACHINE [email protected]

SILICONE BAG FOR PVB AUTOCLAVE VACUUMING [email protected]

www.ucolin.com www.silicone4.com

The storage and protection of PVB film when laminating safety glass with Polyvinyl Butyral PVB film

Warehouse condition:

Indoor, Normal temperature, humidity lower than 65%

Storage period:

To be stored in buyer’s warehouse less than 24monthes after the producing date

Don’t open the package if it’s not used immediately.

Prevent the package from getting wet.

Put the PVB film into the combining room for at least 24 hours before use.

The rest PVB film must be stored in a room with temperature and

moisture control.

======================================================

Glass cleaning and requirement when laminating safety glass with Polyvinyl Butyral PVB film

Purpose:

Erase any oil or dust on the glass surface

Enhance adhesion capacity

Basic condition and requirement:

Clean the glass. City-water is available

Rinse the glass with treated water only.

Water quality requirement: <30 uS or >1M Ω,Hardness <10ppm,Water

temperature 40-60℃

The glass must be dried completely. Both hot wind and cold wind are

workable, but the wind should be filtered first so as to prevent

contamination.

=========================================

All Rights Reserved By:

UCOLIN SILICONE TECH

(1)-Silicone Vacuuming Bag for EVA Glass Laminating Machine/Privacy Glass Laminating

(2)-Silicone Sheet for EVA Glass Laminating Machine

(3)-Silicone Bag for PVB Glass Laminating Auto-clave

(4)-Silicone Rubber Sheet for Solar Cell Module Laminating Machine

(5)-Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine Vacuum Filming Machine

Contact Us: [email protected] / www.ucolin.com

[email protected]/ [email protected]

===========================================

Requirement for combining room when laminating safety glass with Polyvinyl Butyral PVB film

Basic condition and requirement:

Temperature: 20-25℃

Humidity: 23% +/- 2%

Double doors

Indoor air must pass through the filter

A carpet able to suck up the dust should be put between the double doors.

It’s necessary to keep clean the indoor floor and devices.

Operating workers must wear clean overalls that will not be dehairing,

and also wear glove and cap to prevent causing contamination.

=============================

Glass combining when laminating safety glass with Polyvinyl Butyral PVB film

Note: glass surface temperature: 20-40 ℃,

Suggest control temperature: 25-30 ℃

If temperature is higher than 40℃:

The PVB film will get shrink;

PVB film wrinkle will appear;

The film will get sealed earlier than expected;

The PVB film will get soft and adhere to the glass;

There will be lots of air inside the film.

If temperature is lower than 20 ℃:

The PVB film surface will be too smooth to get fixed;

It will be very difficult for the glass and the PVB film to get adhered;

It will be difficult to get rid of the gas and trim the edge of the

laminated glass;

There may be flaw on the edges.

PVB film temperature: 20-25℃

Combining process:

The PVB film should be 5-10mm bigger than the glass;

The PVB film is put on the glass on level stage;

The PVB film can not be pull when its edge is being trim;

2-5mm PVB film should be left on the edge after trimming.

The four edges of the upper glass should be aligned with that of the down glass.

Check carefully whether there’s any contaminating stuff on the glass or the film.

===========================================================================

Prepressing and air expelling when laminating safety glass with Polyvinyl Butyral PVB film

Purpose:

To get rid of the air leaving between the glass and the film

To pre-combine the glass and the film before it’s put into the autoclave

To seal up the edge in order to avoid the air permeating into the laminated glass again.

All Rights Reserved By:

UCOLIN SILICONE TECH

(1)-Silicone Vacuuming Bag for EVA Glass Laminating Machine/Privacy Glass Laminating

(2)-Silicone Sheet for EVA Glass Laminating Machine

(3)-Silicone Bag for PVB Glass Laminating Auto-clave

(4)-Silicone Rubber Sheet for Solar Cell Module Laminating Machine

(5)-Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine Vacuum Filming Machine

Contact Us: [email protected] / www.ucolin.com

[email protected]/ [email protected]